Automation with ENGEL: uncomplicated, efficient, cost effective

The linear robot as a stand-alone version

In legacy applications, linear robots are deployed directly on the injection moulding machine for pick and place operations. But they can do far more: the stand-alone version of the viper 40 linear robot plays the leading role in the automation solution for pool and pool accessory specialist Steinbach's production. It connects the e-motion machines with the high-bay warehouse and handles palletising tasks. And it does all of this inexpensively, quickly, and on a small footprint. Its use has therefore lead to a significant increase in efficiency at a highly automated plant.

This is how the linear robot leads to more efficiency in production

The use of a linear robot as a stand-alone version in production increases efficiency through automation. From the delivery of the raw materials to the dispatch of the palletised end products, the complete flow of goods is automated.

These steps are performed by the linear robot for Steinbach:

- Automated production of sales packaging for swimming pool care products.

- Fast and fully automatic filling of the products.

- Automatic communication with the high-bay warehouse.

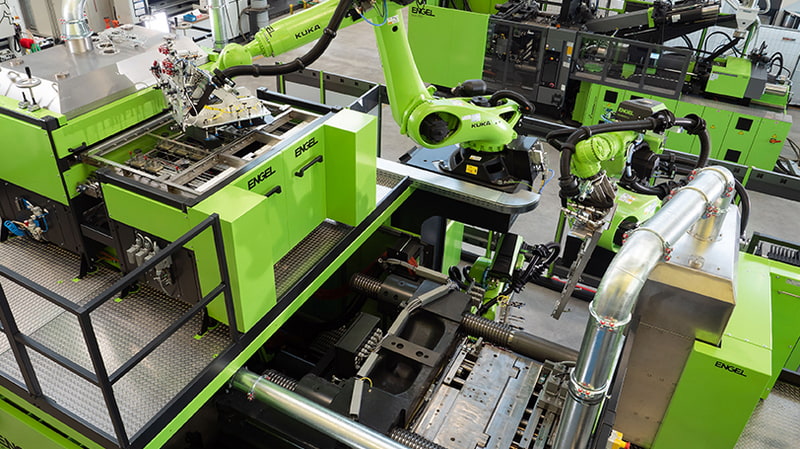

Two blow moulding machines and three ENGEL e-motion injection moulding machines are used to produce three different plastic containers.

Production 4.0 with linear robots: The best choice for this application

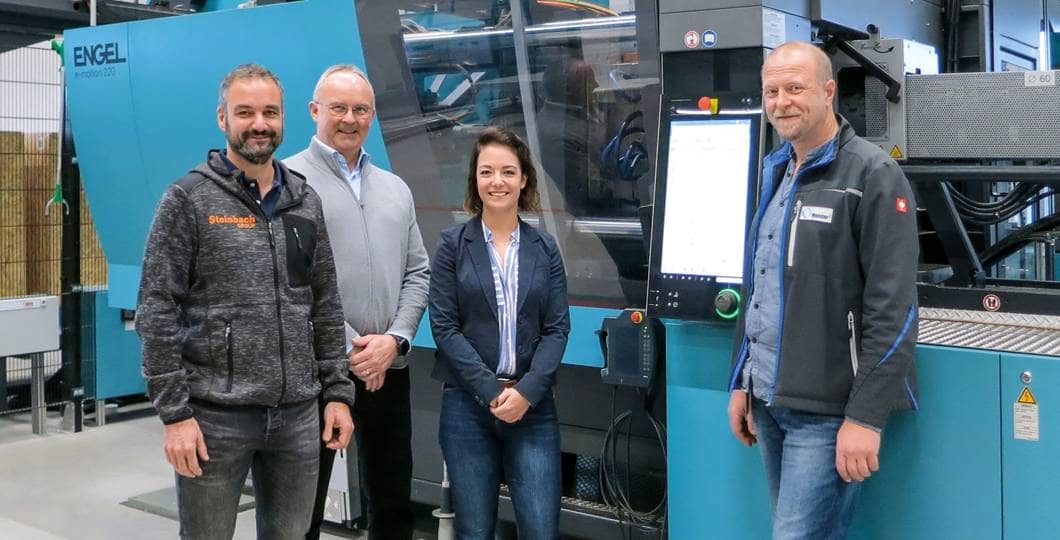

The stand-alone version of the viper 40 linear robot plays a central role. It communicates with the warehouse management system and connects the two e-motion machines used for producing the container caps with the high-bay warehouse. "We have taken a totally new approach here", says a thrilled Meister. "After all, palletising tasks are something that linear robots are normally not expected to handle." Steinbach initially envisaged an articulated robot in its concept planning. "But we would not have achieved our efficiency objectives", Meister objects. "The linear robot is cheaper, needs less space, is easier to operate, and even faster when it comes to stacking. We now have the simplest, most efficient and most cost effective automation solution. Linear robots open up far more options than many processors believe."

Customised software solution for linear robots

Programming the software turned out to be trickier than the mechanical implementation. ENGEL's automation experts developed a solution specifically tailored to the range of requirements, including interfaces to the warehouse management system. A new C10 generation hand-held unit with a particularly large 10" touch display completes the line-up: it offers an even better overview and more convenient operation for palletising tasks.

How 24/7 automation works – a practical example

Operating the stand-alone robot is easy for the plastics engineers at Steinbach; after all, the injection moulding machines are also equipped with ENGEL viper linear robots. The night and weekend production is completely unmanned. Mould maintenance and rare mould changes are carried out on weekdays in two shifts with one operator each. There are time buffers for manual interruptions both on the injection moulding machine and the stand-alone robot. This means that production runs 24/7. "We get excellent technology and the fastest-possible service from ENGEL. We have the world market leader right on our doorstep. Of course we are leveraging this advantage." as Hannes Peterseil, plant manager in Schwertberg, confirms.

When we send a service ticket to ENGEL, the technician sometimes reaches the production unit just 20 minutes later. We get excellent technology and the fastest-possible service from ENGEL. We have the world market leader right on our doorstep. Of course, we are leveraging this advantage.

These are the advantages of linear robots:

- Increasing efficiency

Automation from raw material delivery to finished product simplifies the production process and increases efficiency. - Nonstop plant

Production runs even on weekends. Employees can focus on few manual interventions, tool maintenance and changes. - Space-saving

A linear robot takes up less space than a jointed-arm robot, which has often been used for palletising operations. - Wide range of applications

Linear robots can also be used for other applications in addition to their use on an injection moulding machine.

Deborah Lidauer, product manager for automation at ENGEL, is well aware of the often unused advantages of linear robots: "The legacy application for the viper linear robot is serving an injection moulding machine, but there are even more examples on the market where a free-standing viper is used for downstream processes, where it significantly boosts efficiency". For these applications, ENGEL mounts the linear robots on a separate gantry, which absorbs the robot's dynamic action just like the injection moulding machine.

Are you interested in cooperating with ENGEL?

We look forward to receiving your enquiry!

More about our products from the article

System solutions

Tailored automation solutions from a single source

Linear robots

Powerful, flexible and deployable as stand-alone solutions

Services

Injection moulding systems & automation excellent 24/7 support