Increase OEE by 9 % with production management software

Why did KROSCHU need production management software?

KROSCHU was faced with an enormous challenge: the manual documentation of the tool history for over 600 active tools. Every process step from the first set-up to the first good part was recorded. This process required a lot of resources and was prone to errors. It also involved numerous handwritten records and Excel planning papers.

A solution had to be found to replace this laborious process. The decision was made when KROSCHU came across the authentig MES solution at a trade fair. In 2019, the software for machine data acquisition was introduced and manual data maintenance was gradually replaced.

The reasons for introducing production management software were complex:

- Efficient digitalisation and automation of documentation processes

- Minimise sources of error and improve quality assurance

- Free up valuable resources

- Transparent process tracking in real time

- Seamless traceability of every process step

What is ENGEL authentig and how was it implemented at KROSCHU?

ENGEL authentig …

- is a Manufacturing Execution System (MES) software.

- was specially developed for the plastics industry.

- enables the collection of data on machines and production. This revolutionises operational production management.

- provides the basis for strategic planning and control of production with the collected data.

- has a modular structure. Various functions can be implemented as required.

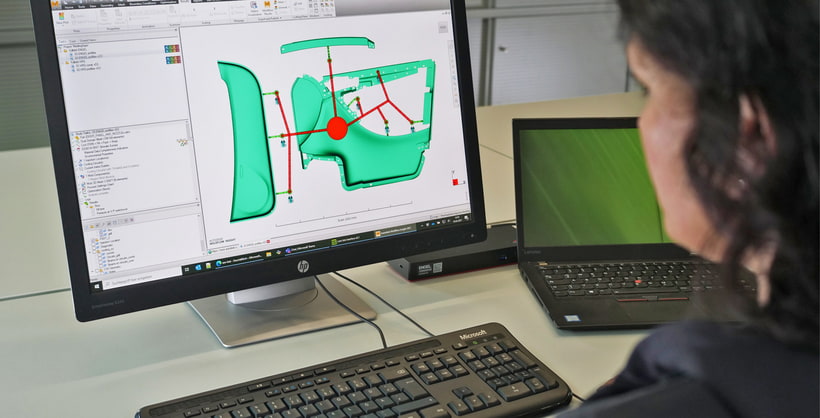

At KROSCHU, all injection moulding machines were accurately networked with the introduction of the production management software. A total of seven terminals were installed for easy interaction between the machine operator and the system. These terminals can be used to display order starts and stops as well as all the necessary documents for the respective production project. In addition, a central terminal in production provides a clear display of the current status of the injection moulding machines.

Buy-in from all the employees at KROSCHU has been there right from the start. The web terminal simplifies daily work processes and increases efficiency in production. This paves the way for modern, data-driven production.

What are the advantages of using production management software in everyday work?

(1) Manual work steps no longer required

The elimination of manual work steps has createddecisive advantages in day-to-day work:

- Repetitive manual calculations of service life are no longer necessary.

- Potential sources of error are drastically reduced.

- Process steps are entered directly in authentig.

- Items are labelled with unique numbers for identification.

- Seamless transfer of production data to authentig for customer orders.

Each cycle of the injection moulding machine is also recorded automatically. This optimises error detection by trained employees and provides additional quality monitoring.

Authentig not only increases efficiency, but also improves the accuracy and reliability of the entire production process.

(2) Communication with the tool shop

The Maintenance module plays a decisive role at KROSCHU. This is because it has a significant role on communication with the toolmaking department.

By creating a project, all relevant content is available for toolmaking at the same time. This not only saves a considerable amount of time, but also ensures a high quality standard and high availability of the tools. Especially with regard to audits, immediate answers to the auditor's questions can be provided.

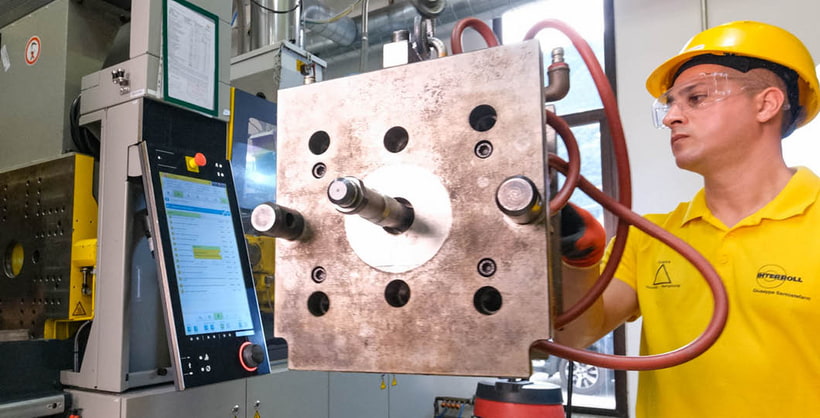

A key aspect is the implementation of defined maintenance plans, which are stored in the production management software. Maintenance intervals are automatically monitored based on the recorded production hours. This enables maintenance work to be announced at an early stage. This prevents machine downtimes, as unplanned mould maintenance no longer occurs.

(3) Processing of complaints

KROSCHU products are sold internationally. As a result, any complaints often only arise weeks after a product series has been completed.

This is where authentig provides significant support. The production management software can seamlessly trace the existing data record. This allows deviations from the desired actual state to be analysed precisely. The cause can also be determined, such as changes to the machine parameters or faulty material.

Manual documentation was prone to errors and tied up resources. Following the introduction of the authentig production management software, every cycle of the injection moulding machine is automatically registered and mapped. By measuring and monitoring the key figures on a daily basis, we have been able to optimise our results.

(4) Process monitoring in real time

The Quality Process module monitors process values in real time. Monitoring warnings and push-up notifications indicate changes to machine parameters or cycle times.

ENGEL's specially developed app enables processes to be monitored around the clock. Thanks to this continuous monitoring, KROSCHU can react immediately if process data leaves the defined tolerance fields. This means that technical personnel are available every production day to eliminate errors.

Read more about the successful process optimisation following the introduction of the Manufacturing Execution System (MES) authentig at a plastics processor in technical injection moulding.

(5) Capacity planning

The Order Management module controls short-term capacity planning. This covers a time window of two weeks of production.

This module can be used to make forecasts. This makes it clear at an early stage whether extra shifts are necessary to cover peak demand. This promotes efficient machine utilisation and helps to optimise personnel and energy costs.

(6) Key figures and statistics

The Reporting module provides KROSCHU with important key figures and statistics (KPIs) from production. These include, for example, reject rates and machine downtimes.

The setup sends the setting data for items to the machine. This data is saved for each item.

Conclusion: 9 % increase in Overall Equipment Effectiveness (OEE)

The implementation of ENGEL authentig at KROSCHU represents a turning point in the company's plastics processing. The production management software not only revolutionises production, but also optimises the entire working day. The benefits range from efficient documentation to intelligent communication with the mould shop. The elimination of manual work steps and the seamless transfer of production data increases accuracy and efficiency.

At KROSCHU, Overall Equipment Effectiveness (OEE) is measured as standard. This involves multiplying the quality rate, performance level and utilisation level. In the four years of using the software, this value has risen by nine per cent.

Overall, this led to:

- improved efficiency,

- positive cost effects and

- a strategic increase in production performance.

With authentig, KROSCHU has implemented more than just production management software. The company has taken the first step towards a smart factory for the future of plastics processing.

Would you also like to benefit from the advantages of production management software?

We will be happy to help you.

More about our products from the article

ENGEL authentig

Our software for machine data acquisition ensures transparent production

![Simulating injection moulding using ENGEL sim link :] Spritzgießen simulieren mithilfe von ENGEL sim link Picture shows Gianluca Capella working with sim link](/fileadmin/_processed_/1/0/csm_gianluca_cappella_sim_link_01_8d614d3e7d.jpg)