Lighter, more dimensionally stable and more economical components thanks to plastics foaming

How does foam injection moulding work?

You're probably familiar with this: you open a bottle of coke which has been shaken thoroughly beforehand, immediately foam shoots out of it and spreads generously in the vicinity. In principle, foam injection moulding works exactly the same way! A propellant is added to the material (in the case of coke, this is the carbonic acid) which dissolves evenly in the material due to high pressure and high temperature (corresponding to the shaking of the coke bottle). If the pressurised polymer gas solution is injected into the mould cavity (or if the coke bottle is opened), this causes a sudden drop in pressure in the material, the mixture becomes supersaturated and the dissolved gas escapes to form foam. The only serious difference in foam injection moulding (called foammelt at ENGEL) is: In contrast to the coke experiment, the process takes place under controlled conditions - after all, we want a functioning component at the end and not a mess.

Our partner company Trexel™ shows an overview of the foam injection moulding process:

What are the advantages of foaming plastics?

- Lighter components

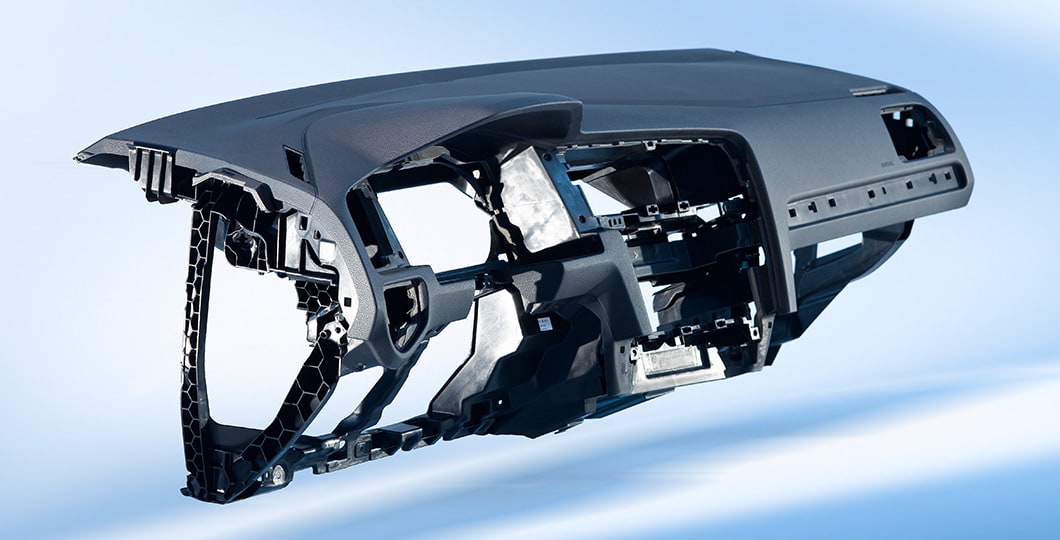

Foamed components are significantly lighter than conventional injection moulded parts, as part of the material is replaced by gas. - Less distortion

In addition, foaming ensures a homogeneous internal pressure in the cavity, which significantly reduces distortion and makes the components more dimensionally stable. - Economical process

Last but not least, the foammelt process is economical because less material is needed, the cycle time can be reduced due to the elimination of the holding pressure phase and larger parts can be produced on smaller machines due to the significantly lower clamping force required. More on this in the next paragraph.

What types of foam injection moulding are there and what do I need for it?

Basically, there are two foaming processes, which differ in the type and insertion of the blowing agent into the polymer: The physical and the chemical foaming.

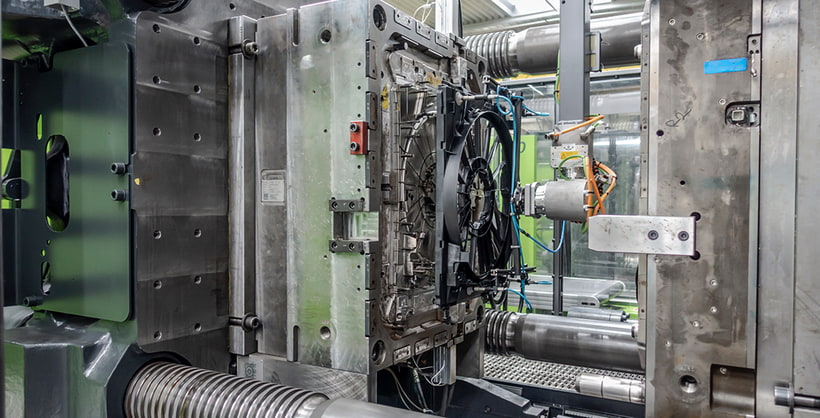

- In physical foaming, gas (usually nitrogen or carbon dioxide) is introduced into the melt after plasticising. This requires additional equipment. Which gas is used depends on the component geometry and the desired end use.

- In chemical foaming, a blowing agent in granulate or powder form is added to the primary material. The subsequent plasticising process melts the blowing agent and releases gases (this process would be like Mentos in a coke bottle). Chemical foaming does not require any additional equipment and is therefore easier and cheaper to implement.

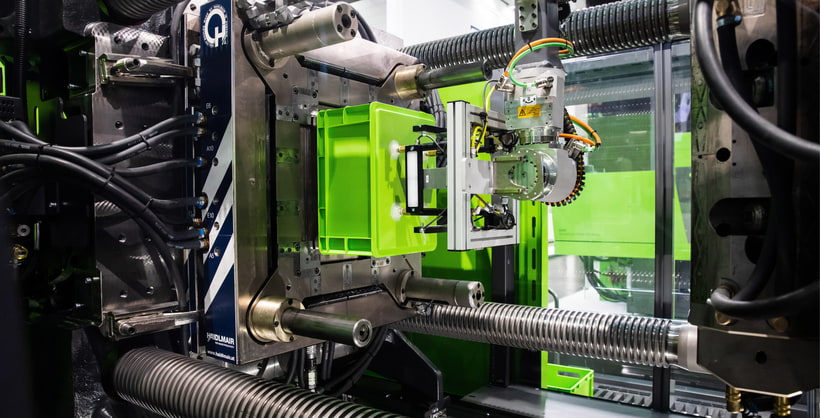

What both processes have in common, is that the melt viscosity is reduced. As a result, the cavity pressure is considerably lower than in compact injection moulding, which on the one hand has a positive effect on the service life of the mould and on the other hand also leads to a reduction in the clamping force. Very often, the lower clamping force also leads to smaller machines, which in turn reduces the investment. Our patented, tie-bar-less ENGEL victory series is predestined for the production of large components on smaller machines.

Lighter components thanks to plastic foams - the most important facts at a glance

- How it works: A blowing agent (gas) is dissolved in the material. Injection is accompanied by an abrupt drop in pressure, causing the gas to escape while foaming.

- The advantages: Plastic foaming is economical, it reduces delay thanks to homogeneous internal pressure in the cavity, and it produces lighter components.

- What is needed: Gas and additional equipment for its injection (physical foaming) or only blowing agent (chemical foaming), with no need for further equipment.

How can I find out more about foam injection moulding?

Simply contact our experts - we will be happy to provide you with comprehensive advice and work with you to develop a solution tailored to your individual requirements. In addition, a foammelt conference is held at ENGEL every year with many interesting lectures on all aspects of foaming.

ENGEL foammelt conference 2020: Wolfgang Kienzl talks about the basics of plastic foaming

Would you like to know more about foam injection moulding?

Our experts will be happy to advise you.

More about our products from the article

Foam injection moulding technology foammelt

foammelt: The ENGEL foam injection moulding process at a glance

The multi-purpose tie-bar-less machine

Perfect for large moulds with low clamping force requirements: Our patented tie-bar-less victory series

Surface technology DecoJect®

DecoJect®: The perfect extension for foam injection moulded parts not only in the automotive interior sector