How to successfully produce high-precision plastic parts

At Samaplast in Switzerland, tie-bar-less injection moulding machines ensure greater efficiency and safety in the cleanroom. The contract manufacturer specialising in clinically pure medical technology operates three cleanrooms for injection moulding where it produces high-precision moulded parts, for example, the ZipFix: a connecting element similar to a cable tie for closing the breastbone after open-heart surgery. This sophisticated product is produced on a tie-bar-less hybrid machine. Of the 28 injection moulding machines at the site today, only four machines still have tie-bars.

Injection moulding in medical technologies: precise and clean process flow

Of all the medical technologies products made of plastic, implants pose the strictest requirements for the manufacturing process. ZipFix is also a two-component product, because at the end of the long tongue there is a curved needle to thread the tie through the tissue between the rib arches. Overview of the production of these high-precision plastic parts:

- The needles are rinsed with ultrapure water in an airlock cleaning system, dried and fed directly from the cleaning chamber into the cleanroom. The needles are then manually inserted into the multi-cavity mould.

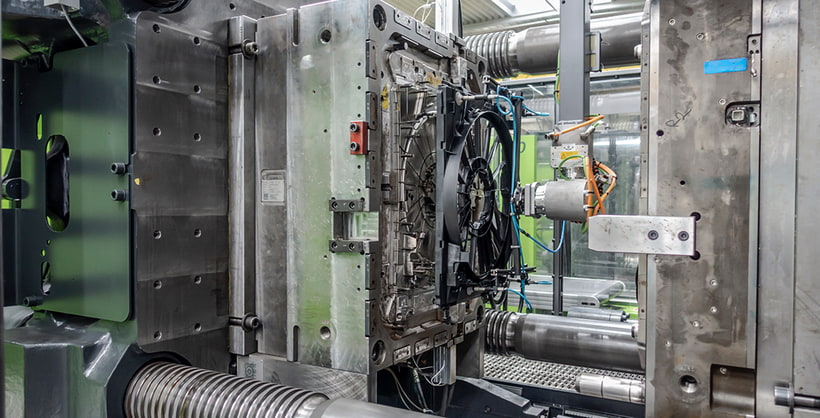

- The needles are overmoulded with PEEK on an ENGEL e-victory hybrid machine with electric injection unit and servo-hydraulic, tie-bar-less clamping unit in cleanroom design. High precision during injection and part removal guarantee maximum quality.

- After the injection moulding process, the ZipFix elements are removed by an employee, visually inspected, measured, laser-marked, and packed in sterile packaging. One benefit which tie-bar-less technology offers is improved ergonomics. There is no need for employees wearing protective overalls to bend down and reach between the tie-bars.

Teamwork with ENGEL Switzerland and the Medical Technologies Department in Austria works very well. They are always receptive to our individual requirements, and the local ENGEL team also has an in-depth understanding of medical issues.

What is important in injection moulding for medical technologies?

Advantages in the cleanroom were decisive for the tie-bar-less technology. Tie-bar-less machines and a barrier-free clamping unit keep the production of the high-precision plastic parts clean. The e-victory's hydraulic system is hermetically sealed. Samaplast uses only food-grade H1 oils, which are delivered to the ENGEL plant for initial filling. The ecodrive servo-hydraulic system ensures that the heat and particle load transferred to the cleanroom is reduced because no energy loss in the form of heat needs to be dissipated by the hydraulic oil.

More efficiency, lower costs

Flexibility in injection moulding for medical technologies: as a contract processor Samaplast needs flexible machinery. Only a few individual applications run for several weeks. However, only a few hundred of some other products are needed each year. This means frequent mould set-ups. And here, too, tie-bar-less technology comes into its own. The extra freedom of movement in the mould installation space makes it possible to mount very large moulds on small injection moulding machines. This efficiency factor is particularly beneficial in cleanrooms: the smaller the machine, the lower the emissions. The lower space requirement and reduced energy consumption with consistently high part quality result in lower costs.

Do you come from the medical technologies sector and are you interested in efficient solutions for cleanrooms?

Our experts are always happy to help you.

More about our products from the article

The universal tie bar-less machine

Maximum freedom in the mould area: our patented, tie-bar-less hydraulic injection moulding machine, the ENGEL victory

The hybrid tie-bar-less machine

The best of two worlds: the tie-bar-less hybrid ENGEL e-victory injection moulding machine