co-injection: Sequential injection moulding for food packaging

What are sandwich processes?

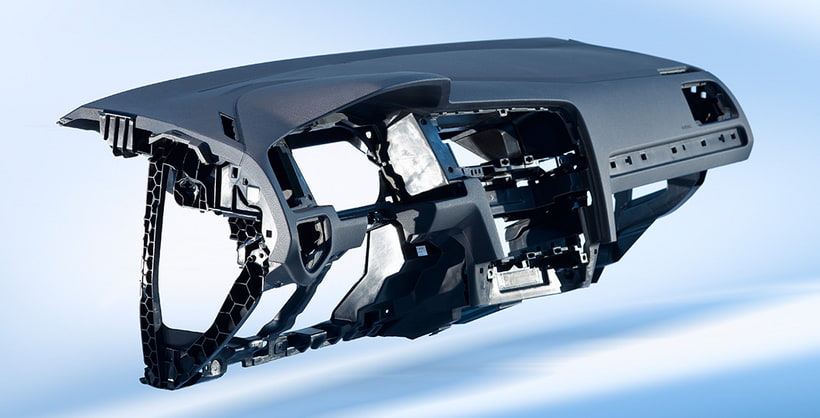

A detailed treatment of sandwich injection moulding has already been covered here in the ENGEL blog, see the article Types of Sandwich Injection Moulding - Functionalities & Applications. In brief, sandwich injection moulding involves introducing two different materials into the mould cavity in such way that a three-stage layer structure is achieved in the injection moulded part in cross-section: skin component - core component - skin component. Through the intelligent combination of different materials, specific improvements in the properties of the component can be achieved.

What is the benefit of the sequential injection moulding process co-injection?

In contrast to the ENGEL skinmelt sandwich process, which uses the dosing method, the sequential ENGEL co-injection process has a decisive advantage, especially for food packaging: since the sprue sealing and the application of the holding pressure are carried out with the skin component in sequential sandwich injection moulding, the core material is completely surrounded by skin material at the injection point.

Why sequential injection moulding for food packaging?

In principle, the sequential injection moulding process co-injection enables the sandwich technique to be used shrewdly for food packaging by completely enclosing the core material: Since the surface in food packaging must consist entirely of food-grade materials, the skinmelt method is no longer an alternative for this area unless a plastic approved for use in the food sector is also chosen for the core material. In this case, however, one of the greatest advantages of the sandwich process would be lost.

The co-injection process makes it possible to use recycled material in the food sector, for example. The technology offers complete enclosure of the recyclate, thus ensuring that only food-grade material comes into contact with the product.

What are the benefits of sequential injection moulding for food packaging?

Since the core component in co-injection does not necessarily have to be food-safe, a significant reduction in material costs can be achieved by using cheaper plastics for the core area of the packaging - especially if a material with a higher density and stability is chosen for the core and these properties are used to specifically reduce the wall thickness and thus the total amount of material used. Furthermore, in contrast to the skinmelt process, the ENGEL co-injection unit eliminates the need to transfer the core component to the injection unit for the skin component - switching between the two materials takes place directly in the co-injection unit. The sequential sandwich process co-injection is therefore particularly suitable for productions where the cycle time is decisive for economic efficiency - for example in the packaging sector. In addition, this method also simplifies the setting and operation of the process, which is roughly equivalent to normal two-component operation.

The possible applications for the co-injection process are vastly varied and depend primarily on the choice of material pairings: For example, the core material can serve as a barrier layer for food packaging, it can be used for structural reinforcement as well as for weight saving. In addition, the use of recycled or foamed material for the core is also a popular method to save costs. A particularly decorative marbling effect can be achieved by using differently coloured variants of the same material and switching between the two components several times.

Does the sequential injection moulding process co-injection also have disadvantages?

Yes, this technology also has limitations: For example, no hot runner is possible when using the co-injection unit. Furthermore, the distribution of the wall thicknesses cannot be influenced by the available process parameters. When designing and constructing the components to be produced, special care must be taken to ensure that, on the one hand, the core component cannot penetrate any weld lines and, on the other hand, tends to drift inwards in corners. We therefore recommend providing corners and edges with a slight radius and avoiding weld lines as far as possible in the design.

We will be happy to advise you individually on the optimal

application possibilities of co-injection for your purposes!

More about our products from the article

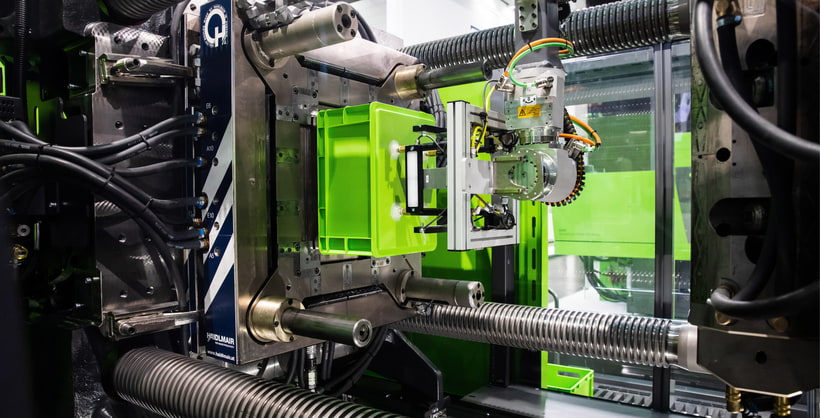

Fast two-platen machine duo speed

The fastest two-platen machine from ENGEL especially for the production of larger pails and packaging goods: Our brand-new duo speed!

Sandwich injection moulding

Sandwich injection moulding methods - an introduction to the world of co-injection and skinmelt

Systems solutions

We offer you not only technological know-how and an injection moulding machine, but a holistic solution tailored specifically to your requirements.