Reduced wall-thickness for thin-walled packaging: From the thin-wall to the ultra-thin-wall pail

The trend towards reduced wall-thickness for thin-walled packaging

The trend towards reduced wall-thickness for thin-walled packaging goods is primarily based on economic considerations: In the case of injection moulding machines, which run in continuous mass production, the material input contributes up to 70% to the total costs of ownership - even a small reduction in the weight of the individual product therefore has a high overall impact on the profitability of a production plant. But where to save material without compromising the functionality of the packaging? Handles and lids - the functional structures on packaging - need a certain amount of material reserve to fulfil their purpose safely. Thus, the material saving is mostly made by reducing the wall thickness.

Save material consumption with thin-wall packaging

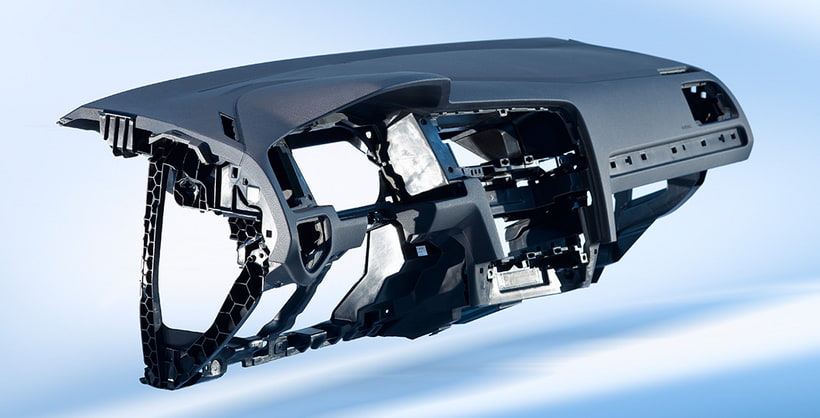

In the production of a 1 L pail on a mould from BRINK Moulds & Automation, this approach was taken into account in the design of the product and mould: by reducing the wall thickness to 0.4 mm, the part weight and thus the material consumption could be reduced by 20% to 21.56 grams. The label of the pail is applied using the IML process, is made of the same material and, in addition to simplifying recycling, also contributes to the stability of the pail.

What requirements does a reduced wall thickness for thin-wall packaging place on the injection moulding machine?

Reduced wall thickness in thin-wall packaging requires injection moulding machines that can cope with the demanding production process. Special requirements are therefore placed on both the injection unit and the clamping unit.

Demands on the injection unit: highest dynamics

The thinner the packaging, the more extreme the flow path/wall thickness ratio. To achieve a smooth process and to ensure a consistently high part quality, two aspects are particularly important:

- High injection dynamics: machines tailor-made for the production of thin-walled packaging achieve injection speeds of up to 1,200 mm/s. In addition, they feature high acceleration to achieve these speeds even with the very short injection strokes customary in the industry.

- High process consistency: ensuring constant process parameters is a challenge with the extreme machine movements. The parameters are subject to a very narrow range of fluctuation, because even the smallest deviations can make the difference between a good part and a reject due to the minimal wall thickness.

For the production of this pail with a flow path to wall thickness ratio of approx. 500:1, we therefore selected our new ENGEL e-speed due to the extreme requirements in terms of dynamics and process stability: this series is tailor-made for the requirements of a modern production line in the thin wall packaging sector. The manufacturer thus achieves and ensures profitable and smooth production of the 1 L pail shown.

The 1L pail is used to show what is possible when the ENGEL e-speed high-speed packaging machine is combined with automation and moulds from Brink. The Brink NOVA technology is used in the mould, which enables an additional reduction in wall thickness and thus weight savings.

Requirements for the clamping unit: maximum output

As already mentioned, in the packaging sector we are mostly in the mass production sector. Output maximisation and the associated increase in profitability are important success criteria here. On an injection moulding machine, this can be achieved primarily through shorter cycle times in some packaging applications, cycle times have been reduced to less than 2 seconds.

Two aspects are decisive for this on the clamping unit:

- Efficient drives: read more about the hybrid machine layout that we at ENGEL are implementing on our e-speed in the last paragraph.

- Highly stable mechanical components

The resulting higher investment costs are compensated for in several ways over the life cycle of the injection moulding machine:

- Via the reduction in material costs mentioned at the beginning of this article

- About the increase in output

- About the reduced maintenance effort and thus decreasing maintenance costs

The targeted design of the individual mechanical components and drives of our e-speed result in a machine that not only offers the highest dynamics and reproducibility, but also low maintenance. With our customised ENGEL care service packages and our predictive wear measurement, unplanned downtimes can be avoided and planned downtimes kept as short as possible.

Turnkey solution for the production of thin-wall packaging products with IML

The drive concept - energy-saving yet powerful

To keep energy costs low and at the same time cope with the high dynamics on the injection and clamping side, a well thought-out, efficient drive concept is needed. A hybrid machine layout has proven to be the most suitable in the thin and ultra-thin wall sector: Servo-electric drives combined with intelligent control of the battery for the hydraulic injection unit. A kinetic energy storage system for the reduction of energy peaks thus offers further savings potential for producers with load-dependent electricity tariffs.

All in all, this drive concept makes it possible to achieve

- high performance

- stable processes

- at a comparatively low energy consumption.

The energy analysis of the e-speed in the practical example shows the potential of a modern high-performance injection moulding machine for the packaging industry: a specific energy requirement of just 0.763 kWh/kg combined with high output ensures profitable production.

Injection moulding machine for thin-wall packaging with reduced wall thickness: Here's what you should look out for

- Customised machines achieve high injection speed and acceleration. Both are necessary for a safe production process.

- With the right injection moulding machine, you maximise output through shorter cycle times. The key factors here are the efficiency of the drive and the use of highly stable mechanical components.

- A hybrid machine layout and a kinetic energy storage system offer further potential for savings.

You want to know more about the application shown

or about our e-speed series?

Our experts look forward to supporting you.

More about our products from the article

High-speed machine

ENGEL e-speed - the hybrid high-performance injection moulding machine for the efficient production of thin-walled packaging