Boosting efficiency in production: standardised automation

The demand for standardised robots is increasing worldwide; after all, they do make a major contribution towards boosting efficiency improvements in production – in terms of both cost effectiveness and power. The new pneumatic pic A sprue picker offers a compact as well as a flexible solution. It cuts and separates sprues and removes small moulded parts. The pic A is the first pneumatic sprue picker that relies on a swivel arm. It helps ENGEL to guarantee high availability and efficiency in production.

Boosting efficiency in production through durability and compactness

The pic A is ground-breaking. This new development by ENGEL aims to be the most durable and compact sprue picker on the market. It is already clear that the ENGEL sprue picker offers significant advantages for the user. The fact that the robot arm can be fully retracted and no longer needs to be swivelled for the mould set-up means valuable time is saved when setting up the machines.

The efficiency of the injection moulding machine is significantly improved by quick and simple mould set-up processes. Standardised automation enables ENGEL to make a valuable contribution to the cost effectiveness of injection moulding production.

The advantages of standardized automation in production:

This is what the pic A from ENGEL can do

Saving space in the application

The pic A from ENGEL is the first robot on the market to feature a swivel arm as a pneumatic sprue picker. This replaces the rigid x-axis, making the new kinematics possible in the first place. The idea for this was provided by the e-pic robot from ENGEL. In addition to this, the pic A is a great space saver because it does not need a rigid x-axis. High levels of precision and safety are achieved even in narrow moulds. The Y-axis module can be adjusted in just a few steps.

Indestructible mechanical system

In order to achieve a particularly long service life, the pic A by ENGEL was equipped with an almost indestructible mechanical system. The shock is dampened by adjustable sliding strips and the part removal stroke is extremely torsionally rigid.

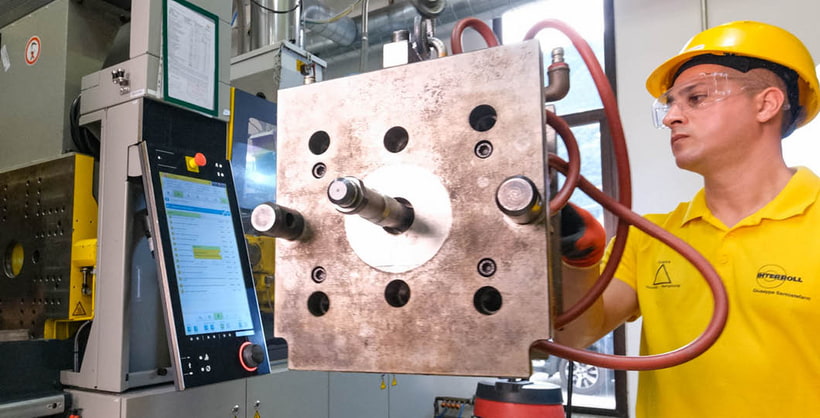

Central operation contributes towards boosting efficiency in production

The control unit of the pic A is integrated with the CC300 machine control unit when deployed on ENGEL injection moulding machines. This allows the user to operate the machine centrally and uniformly from the injection moulding machine display. Efficiency boosts are also generated by the uniform operating logic of the machine and robot.

A solution for greater safety

The ENGEL pic A pneumatic sprue picker is fully compliant with the EN ISO 10218 robot standard, including a two-channel shutdown. Users only need one hand to safely adjust the part removal stroke. The adjustment itself is very simple.

ENGEL stands for individual automation concepts for a wide range of injection moulding applications. To boost efficiency in production, it is important to have access to a comprehensive robot portfolio. This is complemented by ENGEL's custom automation expertise. This combination not only leads to a boost in efficiency, but also to greater cost-effectiveness and maximum quality.

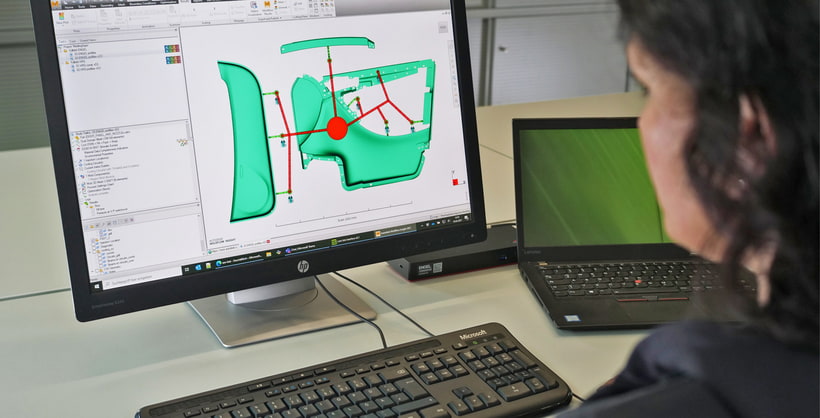

How to increase efficiency in manufacturing through automation

- Use of flexible robots with high performance capacity

- Time-saving and simple setup processes - for example through intelligent swivel arms

- Robust mechanics are the prerequisite for the longevity of a robot and therefore indispensable.

- Optimized workflows - for example through central control and uniform operating logic.

Do you want to make your production even more efficient?

We are happy to support you en route to your individual solution.

More about our products from the article

Picker

Compact sprue pickers and pick & place robots

Robotics Portfolio

Numerous variants of precision industrial robots