How short cycle times go hand in hand with energy efficiency in the packaging industry

Potato or coleslaw, for example, come in the classic 5.5-litre pail. The requirements for producing the lid with originality closure that fits on the pail are a permanent challenge the packaging industry has to face every day. Challenging because production must run as stable as possible with very short cycle times. And all this with low wall thicknesses and long flow paths.

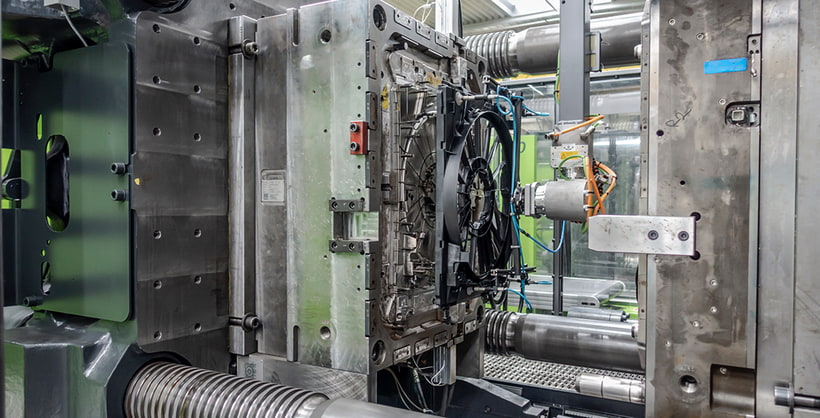

Electric injection even with high clamping forces

To combine high precision with very high performance and energy efficiency, Gerhard Ilsen GmbH & Co. KG decided to invest in an all-electric injection moulding machine. For a year now, the pail lids have been produced on an e-motion with 2800 kN clamping force. The decisive factor is electric injection, which is not possible as a matter of course in the high clamping force range. "ENGEL offers an advantage here," says Philipp Schnell, authorised signatory and technical manager at Ilsen. ENGEL's high-performance machines are offered in full-electric drive technology up to a clamping force of 6500 kN. All main movements are servo-electrically driven across the entire series, which enables parallel movements and ensures extremely high dynamics. Short cycle times, fast injection and cooling are a big issue in lid production, because speed is synonymous with profitability in the packaging industry.

The topics of energy and sustainability are permanently in focus for us, because we are also audited. We were able to save 30 per cent energy already in the first year.

Contribution to increased productivity

Machine downtime is an incalculable problem and was another reason for Ilsen to sound out the injection moulding machine supplier market. "It became clear that ENGEL offered a complete package that precisely met our technical requirements," emphasises Schnell. And rightly so, as we discovered after commissioning the new injection moulding machine. Downtimes on the new machine are virtually no longer logged. Added to this are the short set-up times. "Once the mould setting data and the machine parameters have been saved for a component in the CC300 machine control unit, they can be reproduced again and again," explains Stefan Witt, sales engineer at ENGEL Germany in the Hanover branch. "This gives our customers in the packaging industry a high degree of flexibility." "We start the machine and it runs," confirms Adrian Schnell, Managing Director of Ilsen. "This certainly helps to increase productivity in our company."

It became clear that ENGEL offered a complete package that precisely met our technical requirements.

On the next leap in technology

The e-motion 280 is the first all-electric injection moulding machine in the Ilsen machine park. The investment was accordingly linked to high expectations in terms of energy efficiency. "The topics of energy and sustainability are permanently in focus for us, because we are also audited," says Adrian Schnell. "We were able to save 30 per cent energy in the first year compared to a hybrid machine on which the pail lids were previously produced.”

As the trend is also towards thinner and thinner wall thicknesses for the containers, Ilsen is now setting its sights on an all-electric injection moulding machine technology to produce pails, too. Stacked on a Euro pallet, even the lowest bucket must hold securely and protect the product reliably. This rigidity can only be achieved with a stable injection moulding process.

Are you looking for a sustainable, precise and

at the same time profitable solution?

We have the right offer for you.

More about our products from the article

All-electric e-motion

The all-electric injection moulding machine for high-end applications in the packaging industry

High-speed machine e-speed

The high-speed machine for extreme flow path/wall thickness ratios and multi-cavity moulds with shortest cycle times

Precision machine e-cap

The tailor-made solution for the efficient production of caps and closures