Optimising production processes for high quantities at SLG

Why production processes in custom injection moulding need to be optimised

Ensuring consistent quality is one of the biggest goals in the series production of plastic components. However, various factors can influence the injection moulding process, leading to fluctuations in the components:

- Fluctuating quality of raw materials

- External influences such as temperature or humidity

- Lack of qualified specialists

- Need for regular adjustments to the injection moulding parameters

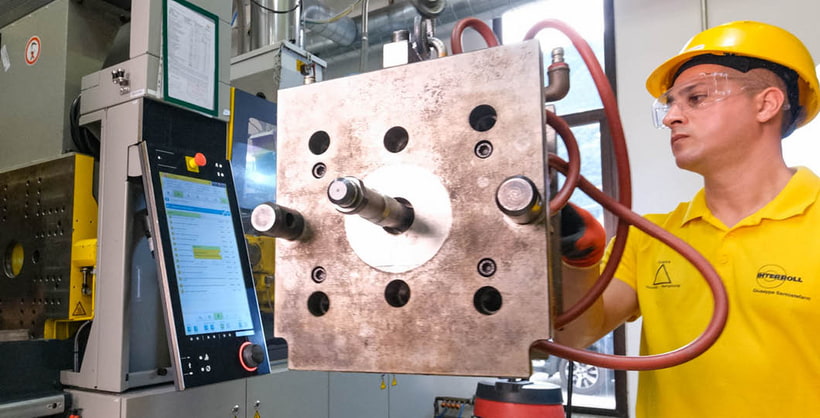

This was also the case for our customer SLG Kunststoff GmbH, a family-run company in the southern Black Forest. With around 300 employees, they produce high-quality plastic injection moulded parts for various industries.

What possible solutions are there for optimised production processes?

In injection moulding, digital solutions can help to optimise production processes and increase transparency, among other things.

Our Parameter-Limits in particular offer an effective solution for keeping production quality stable. After sampling new tools or optimising existing components, application engineers determine the ideal injection moulding parameters. Thanks to Parameter-Limits, these values can only be adjusted within a specified tolerance range.

This prevents uncontrolled changes and reduces the need for continuous process optimisation by technicians, thereby optimising production processes and reducing errors.

Parameter-Limits from ENGEL: Everything you need to know about them

What is Parameter-Limits?

Parameter-Limits is an optional function available on all ENGEL and WINTEC injection moulding machine control units. This allows a process window to be defined for up to 150 individually selectable injection moulding parameters, movement profiles and heating settings.

Find out more about Parameter-Limits from ENGEL and how you can optimise your production processes on our product page .

How does it work?

Parameter-Limits ensures validated process settings and provides the machine operator with a framework within which he can operate and produce good parts.

- Injection moulding parameter selection and display: All selected injection moulding parameters are displayed to the process technician on an overview page. They are divided into four groups that correspond to the phases of the injection moulding process. Further groups can be added if required.

- Target and reference values: In addition to the currently set target value, the reference value that was determined as optimal during the optimisation of the production processes or validation is stored. This reference value serves as the basis for the permitted deviations.

- Tolerance definition: The tolerances can be flexibly defined as absolute or percentage values. Alternatively, upper and lower limit values can be entered directly. The tolerance is calculated automatically from this.

- Storage and protection: All defined settings are saved in the part data record. As soon as Parameter-Limits is activated, injection moulding parameters can no longer be changed outside the defined process window.

What are the advantages?

Parameter-Limits brings numerous advantages for injection moulding and the control of injection moulding parameters:

- Safety through validation: The validated process window is displayed directly on the machine and ensures that changes are only made within this area.

- Preventive protection against operating errors: Adjustments to the process window can only be made by authorised employees. This prevents incorrect settings from being made in advance.

- Increased efficiency: All tolerances are immediately available again after a tool change without having to make any new settings.

- Reduction of rejects: By preventing incorrect process settings, scrap production is minimised, thereby optimising production processes.

For more detailed technical information on injection moulding solutions for custom moulders, visit our page on Technical Injection Moulding.

By analysing and adjusting our parameters in detail, we have optimised the production processes. The machines now run more stably, which has a positive effect on the entire production process. Parameter-Limits are the only way to maintain this stability.

What results have Parameter-Limits and the optimisation of production processes with other iQ products achieved at SLG?

SLG was able to significantly optimise its production processes. The most important results:

- Reduction in waste: Waste has been reduced by 0.5%, which increases production quality and efficiency.

- Increase in production volume: SLG increased its production volume by 60,000 parts per year, which better fulfils market requirements.

- Optimisation of the injection moulding parameters: Adjusting the parameters of the injection moulding machines led to a significant improvement in operational stability.

- Increase in machine availability: Machine availability increased by 12%, reducing downtime and making more efficient use of resources.

- Increase in plant efficiency: : Plant efficiency was increased from 73% to 85%, resulting in better utilisation of production capacity.

If you would like to find out more about how digital solutions guarantee success in our customers' plastics production, read our article: Practical success guaranteed: Digital solutions for plastics production.

Conclusion: Optimising production processes - stability and quality through Parameter-Limits

The optimisation of production processes is a central component of efficient series production. Significant improvements have been achieved through the use of Parameter-Limits at SLG:

Reduction in waste by 0.5%, which increased efficiency.

Increase in production volume by 60,000 parts per year in order to fulfil market requirements.

Increase in machine availability by 12% and system efficiency from 73% to 85%.

Thanks to ENGEL's Parameter-Limits, parameters are kept stable within a defined process window, which guarantees consistent component quality and prevents process errors.

You too can benefit from the advantages of Parameter-Limits for stable processes and high component quality. Contact us today to find out how ENGEL can make your injection moulding production more efficient.

We look forward to your enquiry!

More about our products from the article

Parameter-Limits

Parameter-Limits for stable production processes

Digital solutions in injection moulding

Optimise your production processes with digital solutions from ENGEL that help you to monitor and control processes efficiently.

![Simulating injection moulding using ENGEL sim link :] Spritzgießen simulieren mithilfe von ENGEL sim link Picture shows Gianluca Capella working with sim link](/fileadmin/_processed_/1/0/csm_gianluca_cappella_sim_link_01_8d614d3e7d.jpg)