Process optimisation through alignment between injection moulding simulation and production

Why does a data interface between injection moulding simulation and machine make sense?

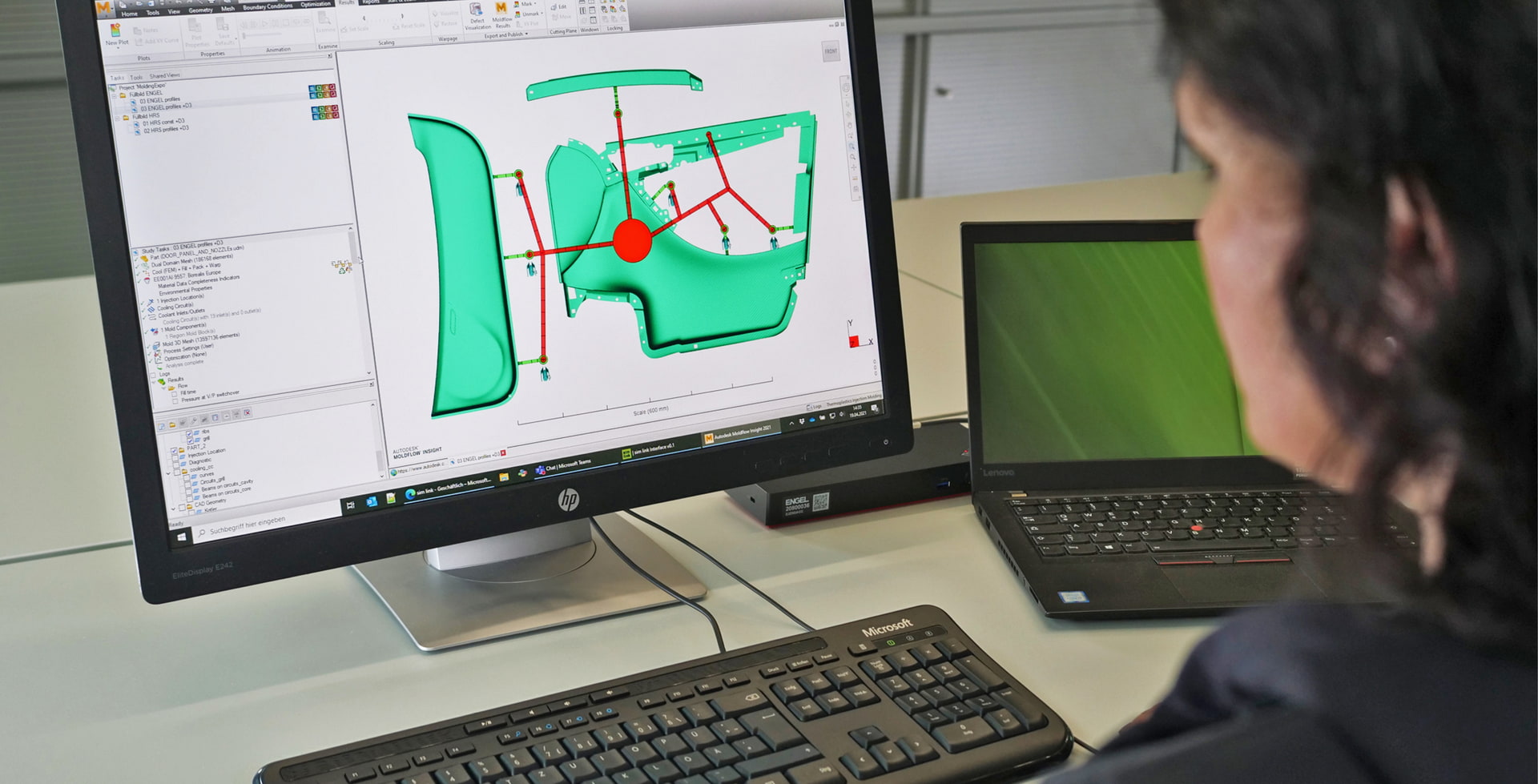

Together with Autodesk Moldflow, we close the gap between the digital twin of the mould and the real injection moulding process with sim link.

The aim of sim link is to link simulation and the real process in order to provide plastics processors with even better support throughout the entire product life cycle - from product development and mould design to ongoing production. Process optimisation in production is achieved by means of appropriate injection moulding simulation and the resulting data.

Here is an overview of the advantages of our sim link data interface:

- Increases the quality of the simulation

- Direct data transfer between simulation and production

- Creates connection without uploading risky data

- Reduces the duration of the start-up phase

- Enables automated data continuity between simulation and production

In the product development process, everyone makes an essential contribution, such as the simulation technician's knowledge of the filling of the cavity(ies) or the process technician's know-how of how to set the machine. With sim link, the exchange of results from injection moulding simulation and production is further promoted and considerably simplified. This offers the opportunity for two disciplines to learn from each other in order to jointly achieve optimal production results.

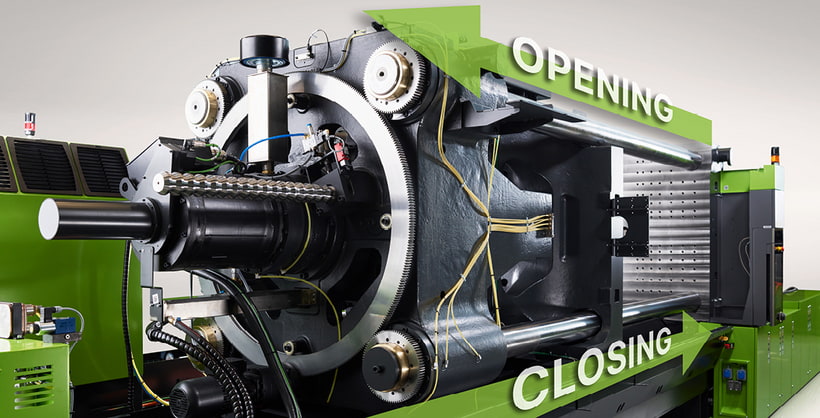

How data transfer between simulation and production works with ENGEL sim link.

Findings from the simulation of injection moulding processes often remain unused on the machine. With ENGEL sim link, the parameters determined from the simulation can now be transferred to a setting data set and used directly on the injection moulding machine. The values transferred from the simulation are converted into setting parameters for use on the injection moulding machine and checked. This initial setting suggestion can be used immediately on the machine and makes a significant contribution to reducing the optimisation iterations on the machine. This eliminates the time-consuming conversion and error-prone manual transfer of the simulation data to the machine - and sim link delivers setting parameters that are optimally adapted for the corresponding machine.

In addition, sim link offers the option of taking into account the machine dynamics of the machine selected for production in order to achieve a more realistic result from the simulation. Conversely, thanks to sim link, process parameters and measurement results from the injection moulding machine can now also be imported into Autodesk Moldflow.

This makes it possible to compare the values calculated in the simulation with the results from the production process and significantly supports the development of know-how.

Would you like to learn more about the possibility of data transfer between simulation and production?

Our experts will be happy to help you.

More about our products from the article

Data interface sim link

sim link is a bidirectional data interface that enables data exchange between the Autodesk Moldflow simulation program and the ENGEL machine in production

Digital solutions

Our digital assistance systems ensure more transparency and efficiency along the entire production process

smart production solutions

Efficiency increase of the machine park, process optimisation, improved resource planning and injection moulding simulation