Types of Sandwich Injection Moulding - Functionalities & Applications

What is sandwich injection moulding?

The sandwich process is a subgroup of multi-component injection moulding, with which it is possible to produce moulded parts that have a structure of at least three layers. This enables you to combine two different material properties. The outermost layers form the so-called skin material. It is responsible for the look and feel of the component. That is why high-quality materials are used here. Inside the component is the so-called core material. Inexpensive materials, regranulates/recyclates, but also foamed materials can be used here. In this way, costs can be saved.

Targeted property improvements can be realised by using reinforced core materials, for example. There are many possible combinations and therefore many different requirements that can be fulfilled. You can find more about specific applications of all types of sandwich injection moulding at the end of this blog article.

The diverse possibilities in terms of recyclate processing, foaming and structural reinforcement of components make the sandwich process an attractive solution for a wide range of injection moulded products. We are consistently driving development in this area and will be happy to find the right solution for you.

What types of sandwich processes are there?

At ENGEL, we distinguish between two basic types of sandwich injection moulding, which differ in terms of process sequence and area of application: co-injection and skinmelt.

co-injection

Co-injection is a sequential process, i.e. skin and core material are injected using two different injection units. In the first filling phase, the mould cavity is partially filled with skin component. Then, in a second filling phase, the cavity is volumetrically filled with core material. Due to the switching from skin to core, flow marks can occur. To counteract this effect, there is the option of a simultaneous phase, a simultaneous injection of both components, which is carried out between the two filling phases. The holding pressure is then applied again with the skin component to compensate for shrinkage.

The advantage here compared to the skinmelt process: Sprue sealing and flushing of the sprue channel is done with skin material, which means that the core component is completely encased in skin material. This is particularly important for injection moulded products for the food industry. For example, a package can be constructed with food-safe skin material and a core component made of recycled material.

skinmelt

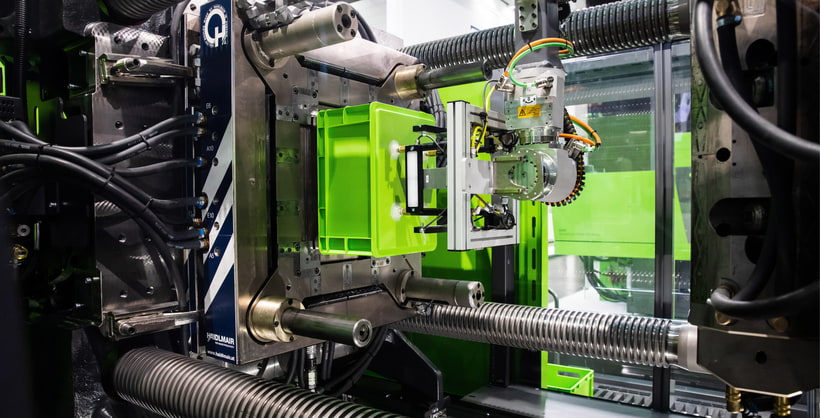

The second type of sandwich injection moulding is ENGEL skinmelt technology: In contrast to sequential co-injection, with skinmelt a predefined volume of the skin component is metered into the mass cylinder of the core component. This results in easier operation and handling, and the actual injection process is similar to compact injection moulding. Since both materials are in the same unit one after the other before injection, an optimal melt flow is ensured and there are no changeover marks on the component. The injection process is completed with the core component, therefore a higher core content is possible.

While this process was presented at the K2019 in Düsseldorf with "intruding" the skin component into the injection unit, there is now the option of actively injecting the skin component into the main unit. The parallel metering of both units in combination with the active injection of the skin component into the main unit can thus save cycle time.

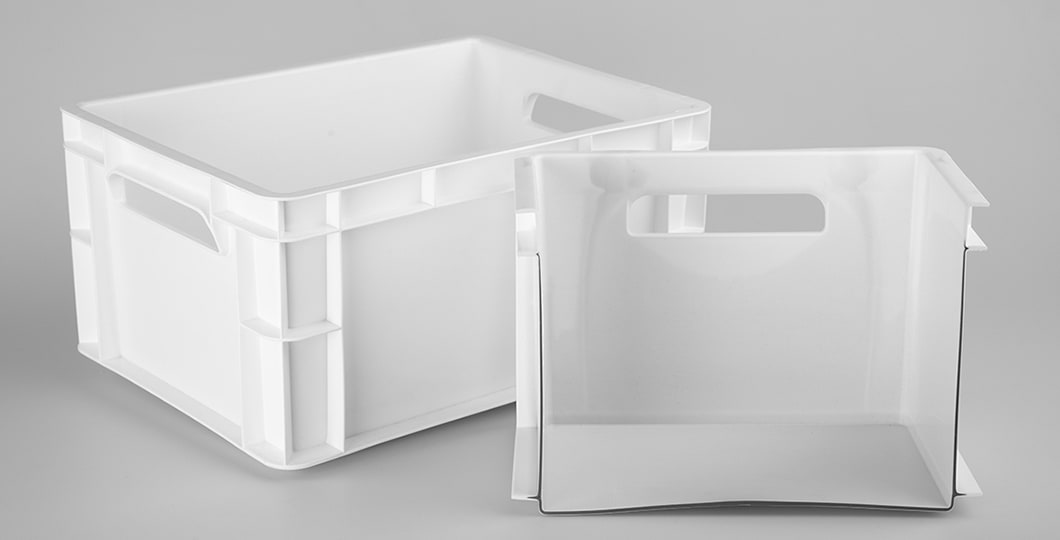

Transport container with recycled core | Sandwich injection moulding

Other frequently asked questions about sandwich injection moulding

Basically, both materials should have a similar processing and tool temperature to avoid excessive distortion during cooling. The exact maximum permissible temperature difference is highly material-specific.

The ratio between core and skin material is strongly dependent on the geometry of the component and the viscosity of the materials. In general, we recommend a wall thickness of at least 1.5 mm in order to achieve the highest possible proportion of core material. To date, we have realised projects with a core proportion of approx. 15 - 65%. In addition to the recommended minimum wall thickness, it has become clear that for a high core proportion, the viscosity of the core material should either be the same or, even better, lower than that of the skin material.

Regardless of the type of sandwich injection molding, the proportion of core material, taking into account the recommended minimum wall thickness, should be as high as possible and at best have a lower viscosity than that of the skin material.

As the core material tends to drift inwards at corners, we recommend not to use corners with too sharp edges when designing the parts - slightly rounded transitions are ideal. In addition, when making openings, consider that the core material cannot penetrate the resulting weld lines.

Yes, the advantage here is that the foamed core minimises sink marks and at the same time an attractive surface can be achieved through the skin material - the typical "streaky" surface of foamed parts does not occur here.

What are the applications for both types of sandwich injection moulding?

The areas of application are defined by the desired effect of the sandwich process. Here are some examples implemented with ENGEL for:

- Weight reduction, cost and material savings through foamed core made of recyclate: logistics products, transport containers as well as pallets, flowerpots, gear levers, handles for power saws and similar tools

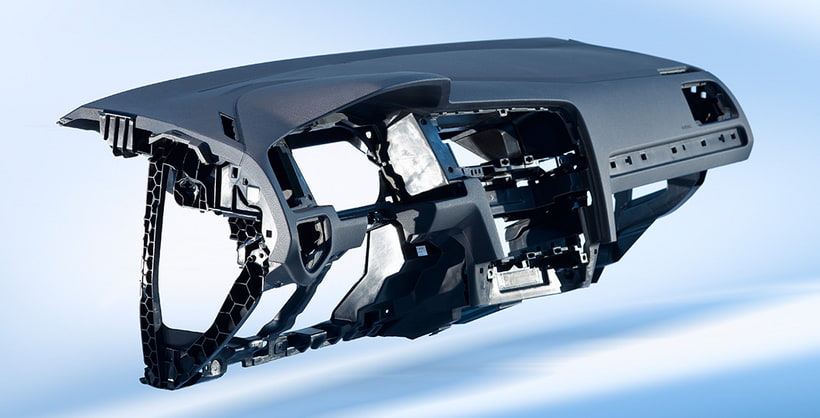

Structural reinforcement with glass-fibre reinforced core: stadium seats, garden furniture, car mirrors

Would you like to know more about the sandwich processes or determine the potential of your products? No problem, we will publish more articles on skinmelt and coinjection shortly - or you can personally contact our experts.

Do you have further questions about sandwich injection moulding?

Our experts will be happy to advise you.