Digital solutions: Practical success guaranteed

Kunststofftechnik Borgmann GmbH, based in Bersenbrück, impressively demonstrates the combination of traditional manufacturing with advanced technological solutions. The company produces high-quality plastic moulded parts for the automotive and furniture industries in three production halls with 42 injection moulding machines - with a clamping force range of 28 to 1000 tonnes. Under the technical leadership of Stefan Borgmann, Borgmann GmbH implements innovative digital solutions from ENGEL to further optimise the efficiency and quality of its injection moulding processes. This forward-looking approach consolidates the company's position as a competent processor in the plastics industry.

Digital solutions in practice: possible applications and advantages at Borgmann

The use of digital products in injection moulding production increases production efficiency. Above all, they help machine operators to set injection moulding parameters correctly. This avoids errors in production and produces higher quality plastic parts.

Borgmann GmbH relies on a combination of various digital solutions from ENGEL:

- iQ process observer for smart process data analysis

- iQ weight control to compensate for fluctuations in plastic viscosity

- iQ clamp control for calculating and optimising the clamping force

- iQ flow control for energy-saving mould temperature control in injection moulding

- e-connect.monitor for condition monitoring of wearing parts and to prevent machine downtimes

- ENGEL EDGE Device for a secure network connection and centralised data processing in Production 4.0

In the following video, Stefan Borgmann reveals how Borgmann GmbH benefits from the use of digital products in production. Discover the concrete benefits and how easy it is to introduce digital solutions in plastics processing.

How the iQ process observer saves 30 minutes per machine every day

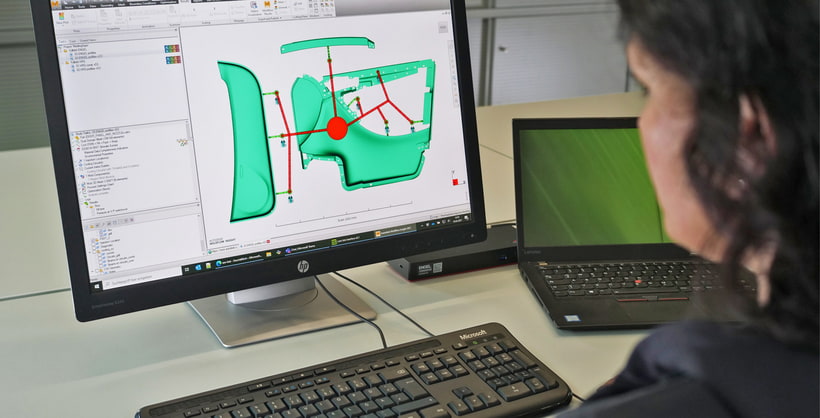

Dimensional accuracy is required for the production of technically challenging plastic parts. Process stability in production is a basic requirement. The iQ process observer software therefore plays a central role at Borgmann.

The iQ process observer is a quick and clear aid for machine operators to analyse and optimise injection moulding processes. Several hundred parameters are automatically recorded and analysed using the software. The results of the process data analysis, as well as AI-supported suggestions for improvement, are displayed transparently on the control system. The iQ process observer differs from conventional analysis tools thanks to its unique combination of AI and expert knowledge. This saves the machine operator a long and time-consuming search for problems.

The huge advantage of the iQ process observer is definitely the good process overview and the speed. When I get to the machine, all I have to do is touch the control unit with my finger and I can see what's going on in the process within a second.

Thanks to the iQ process observer, Borgmann has reduced the time needed to analyse process errors and quality checks by 30 minutes per day and machine. In times of a shortage of skilled workers, increased cost pressure and fast delivery times, this is a decisive advantage - especially for small and medium-sized companies in custom injection moulding. Resources are freed up that can be used for other activities.

The video gives you practical insights into the use and functionality of the iQ process observer in injection moulding production at Borgmann.

Temperature control solutions from ENGEL save energy

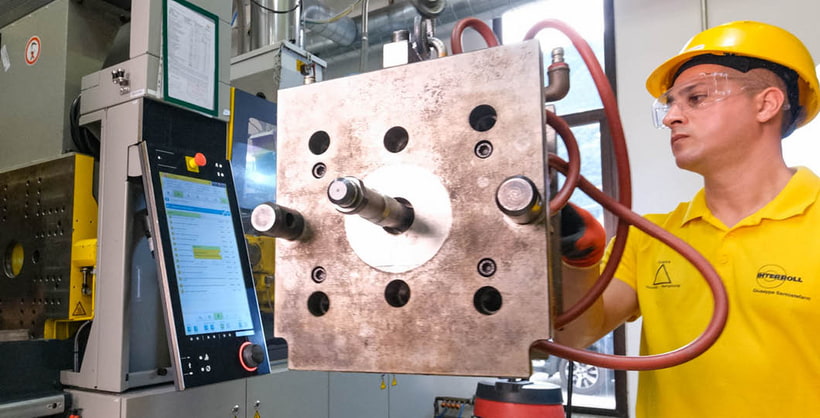

A stable temperature control process in injection moulding is crucial for consistently high product quality. Borgmann relies on the iQ flow control software, the e-flomo water distributor and the e-temp temperature control unit. Together, these systems provide the machine operator with a comprehensive overview of each temperature control circuit in the mould and ensure constant temperature control. iQ flow control independently regulates the flow rate in each temperature control circuit and the speed of the temperature control units to the required minimum.

At Borgmann, the use of these intelligent products leads to more precise temperature control processes and stable production. The temperature control output has been reduced to 70%. The error rate has been reduced. They also benefit from less maintenance work.

Watch the video below to find out how the ENGEL temperature control solutions interact technically during operation and how Borgmann benefits from this.

Stefan Borgmann has achieved impressive and measurably successful results through the targeted use and intelligent combination of ENGEL's digital solutions. If you would also like to use the potential of our digital technologies, we cordially invite you to make an appointment today at your nearest ENGEL training centre. Discover how digital solutions can also increase your production efficiency.

Conclusion: Has the use of digital solutions in injection moulding production at Borgmann paid off?

The answer is: Yes! Borgmann GmbH has achieved significant advantages through the use of digital solutions in injection moulding production:

- Thanks to products such as iQ process observer, iQ weight control and iQ clamp control from ENGEL, production efficiency has been increased and the quality of the plastic parts improved.

- For example, the iQ process observer has reduced the time needed to analyse process errors by 30 minutes per day.

- In addition, temperature control solutions from ENGEL save energy.

These successes show that the use and intelligent combination of digital solutions at Borgmann has definitely paid off.

Do you have questions about the use of digital solutions in your production? Or do you already have the products and need support with implementation?

The ENGEL application technology team will be happy to help you.

More about our products from the article

Digital solutions in injection moulding

Our digital solutions support you on your way to the Smart Factory.

iQ process observer

Our software for analysing process data checks hundreds of parameters simultaneously.

Temperature control

Up to 75% lower energy consumption with ENGEL solutions.

![Simulating injection moulding using ENGEL sim link :] Spritzgießen simulieren mithilfe von ENGEL sim link Picture shows Gianluca Capella working with sim link](/fileadmin/_processed_/1/0/csm_gianluca_cappella_sim_link_01_8d614d3e7d.jpg)