Interroll optimised: Reducing set-up times through digital assistance

The challenge: Efficient injection moulding despite a shortage of skilled workers

Interroll has been a leading global innovator in the field of material handling for over six decades. Headquartered in Switzerland, the company employs around 2,400 people and generated sales of CHF 556.3 million in 2023.

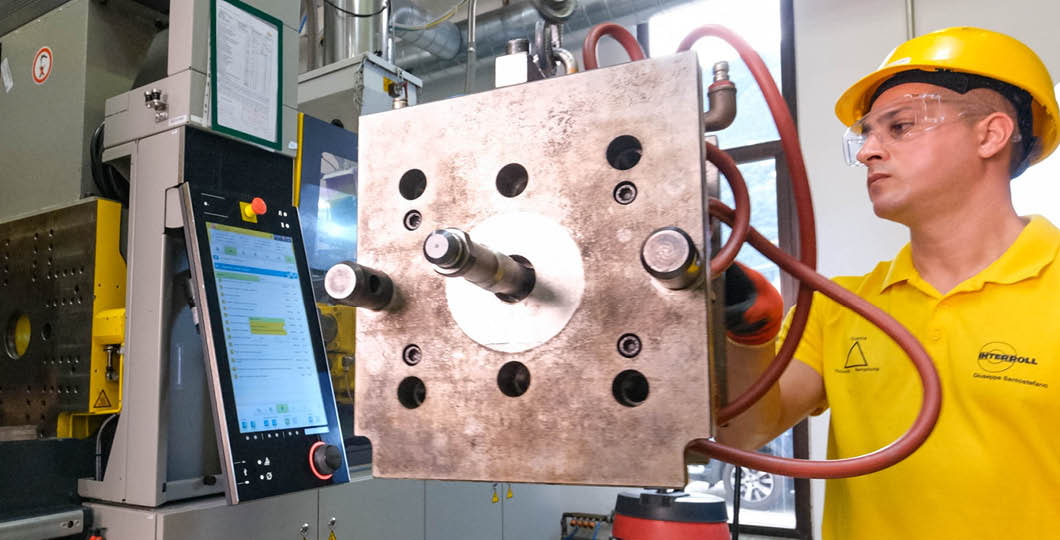

Precise and fast tool changes are essential in production at Interroll in order to be able to react flexibly to customer requirements. "There is a shortage of experienced and qualified labour," explains Piercarlo Balducci, Head of Product Engineering at Interroll. “At the same time, the operation of injection moulding machines is becoming increasingly complex. This means that either well-trained personnel or supporting technologies are required.”

The solution: The digital set-up assistant from ENGEL

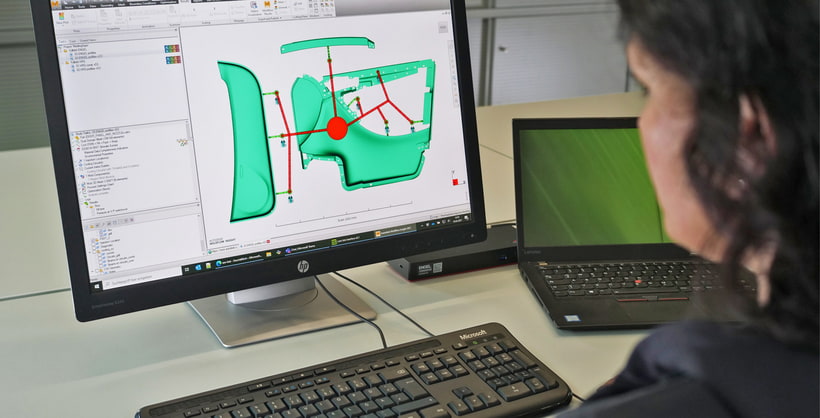

The digital set-up assistant offers Interroll a comprehensive solution for optimising production processes. With a user-friendly interface and interactive step-by-step instructions, the system supports machine operators efficiently when changing tools. Standardised procedures and visual instructions minimise errors and speed up the process considerably.

This leads to a reduction in set-up times of up to 20%, even with complex machines. Thanks to the clear structure of the system, even less experienced employees can quickly work productively and achieve high-quality results.

Interroll about the set-up assistant: Minimise set-up times, increase competitiveness

The result: set-up time optimisation in injection moulding pays off

Thanks to the reduced set-up times, Interroll has significantly increased its productivity. With the set-up assistant, Interroll can work faster and react more flexibly to customer requests. This increase in efficiency not only improves production speed, but also contributes to long-term competitiveness. Thanks to the clear, standardised processes, less experienced colleagues can work safely and without errors.

We used to have to rely on paper-based documentation. Now there is a fixed sequence in the machine control system, both for the assembly and disassembly of the mould. As a result, we have minimised set-up times by 20% and are able to carry out tool changes in just 30 minutes. This is a huge advantage in an industry where speed is crucial and a significant increase in OEE.

Energy efficiency through additional digital assistance systems

In addition to the reduction in set-up time, Interroll benefits from comprehensive digital support through various assistance systems from ENGEL. Particularly noteworthy is iQ flow control. It intelligently controls the temperature control circuits, which significantly reduces energy consumption. Thanks to this technology, Interroll has already achieved energy savings of up to 18%. This is not only economically important, but also contributes to Interroll's sustainability goals.

Conclusion: Set-up time reduction up to 20% thanks to intelligent set-up assistant

With ENGEL's digital set-up assistant, Interroll was able to minimise its set-up times and achieve a reduction in set-up times by up to 20%. At the same time, machine operators benefit from a significant reduction in workload thanks to intuitive and standardised processes.

Your advantages at a glance:

- Set-up time reduced by up to 20%

- Efficient and error-free processes, even with complex set-up procedures

- Support for less experienced machine operators through clear instructions

- Improved competitiveness and flexibility

In addition to the set-up assistant, ENGEL offers other digital assistance systems that support you in the areas of skilled labour shortages and energy efficiency. Read more about this in our blog article: Digitalisation as the key to skills shortages and energy efficiency.

Do you want to increase your competitiveness?

Get in touch with us! We will show you how to reduce set-up times efficiently and safely.

More about our products from the article

Set-up assistant

Reduce set-up times by up to 80% thanks to the set-up assistantt

iQ flow control

Mould Temperature Control in Injection Moulding

![Simulating injection moulding using ENGEL sim link :] Spritzgießen simulieren mithilfe von ENGEL sim link Picture shows Gianluca Capella working with sim link](/fileadmin/_processed_/1/0/csm_gianluca_cappella_sim_link_01_8d614d3e7d.jpg)