Successful validation of iQ weight control with ENGEL support

Which application is the case presented here?

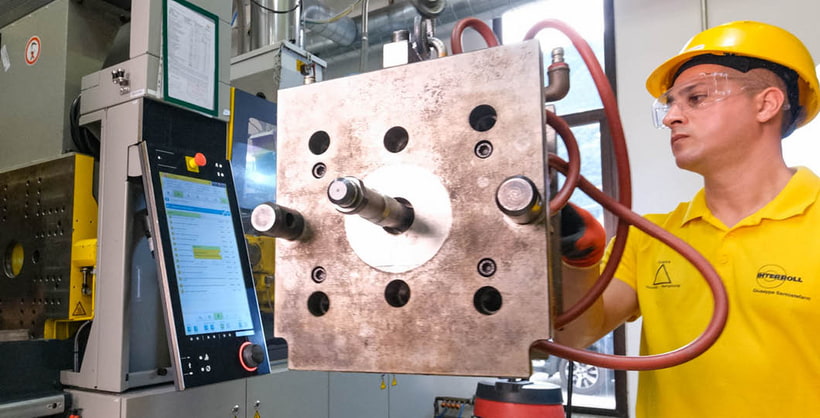

The Intrafix® Safeset infusion device is a million-selling product of the renowned medical technology company B. Braun. An essential component of this device is the roller clamp housing, which enables particularly fine adjustment of the flow rate. This precision component requires a stable manufacturing process with particularly high repeatability. For this reason, the production of this housing has been carried out for some time on all-electric ENGEL injection moulding machines from the e-mac series with the help of the digital assistance system iQ weight control.

How does iQ weight control work?

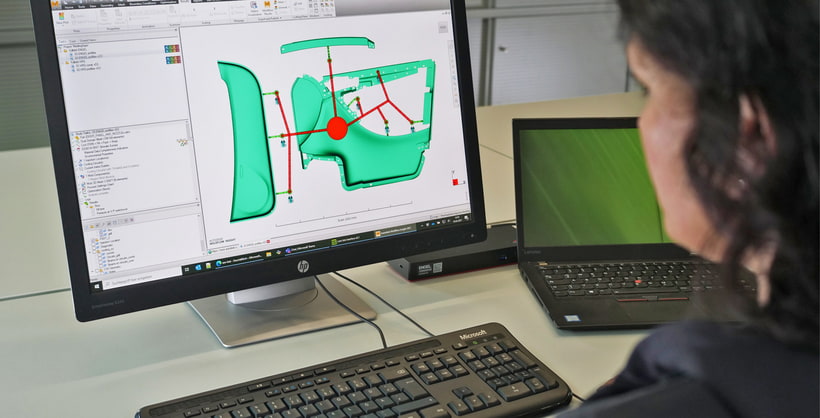

ENGEL's iQ weight control assistance system is a software-based production aid that adjusts process parameters in real time during the injection moulding cycle. This ensures consistent quality of the roller clamp housing. The injection pressure is compared with a reference curve, and deviations in injection volume and viscosity are detected in fractions of a second. Switchover point and holding pressure are automatically adjusted for each shot. This has significantly reduced the need of manual adjustments to the injection moulding process by the machine operator.

Why is validation required?

For medical products that are not documented by full production monitoring or subsequent individual testing of each component, process planning, and the production phase must be comprehensively validated in advance. Since B. Braun's roller clamp housings are used internationally, validation according to EN-ISO and MDR for Europe and according to FDA regulations for the USA was required. The particular challenge for B. Braun and ENGEL arose from the dynamic process control provided by iQ weight control, which, in contrast to the existing, rigid injection moulding process, would have significantly increased the complexity of the validation.

This is where ENGEL was able to make a decisive difference: ‘For us, it was important that the process window is not reduced by iQ weight control. So, we didn't have to adapt our process to iQ weight control. We just used it to adjust the process within the predefined limits,’ explains Andreas Wettlaufer-Ganz, Team Leader of Project/Process Support at B. Braun in Melsungen. “Our system adapts 100% to the product, and nothing needs to be changed in the actual process,” says Norman Buls, medical specialist at the ENGEL site in Hanover, highlighting this important advantage once again.

How does a validation process work?

The validation process in Melsungen consists of four steps to ensure that the process consistently meets the required results.

- First, the limits of the process are determined in DOE (Design of Experience) in a 20-point statistical experimental plan. Based on this, limit values are defined as worst-case combinations that still allow good parts within the tolerance to be produced. These values are stored in the CC300 control unit of the e-mac injection moulding machine.

- The IQ (Installation Qualification) as carried out at the beginning of production - still without the assistance system - and was therefore no longer necessary when iQ weight control was implemented.

- In Operational Qualification (OQ), the defined process limits are checked to ensure that parts that meet the specifications are produced with the worst-case settings.

- In Performance Qualification (PQ), the process is tested over a longer period, with product samples being taken and checked for quality according to the specifications.

What results have been achieved with iQ weight control?

This extensive project naturally had to be prepared accordingly, in particular to be able to better estimate the achievable benefits in relation to the effort. Before the actual validation process, B. Braun therefore carried out its own tests – both with and without iQ weight control. ENGEL examined the influence of iQ weight control on consistent component weight. The results of these preliminary tests showed that the use of the digital assistance system would be worthwhile: The measured deviation with the assistance system was noticeably improved compared to production without support.

‘We can demonstrably speak of a successful integration of iQ weight control here,’ as Norman Buls states. “ENGEL's assistance systems are advantageous for us, which is why we will continue to consider the company in future award discussions,” confirms Andreas Wettlaufer-Ganz.

Conclusion

ENGEL and B. Braun have successfully integrated the iQ weight control digital assistance system for the production of roller clamp housings for infusion devices. The system optimises the injection moulding process parameters in real time, thus ensuring consistent product quality while reducing the need for manual intervention. Before the system was implemented, the process was validated according to EN-ISO, MDR and FDA requirements. The integration of iQ weight control led to a measurable improvement in production quality.

Would you like to find out more about our validation services?

More about our products from the article

GMP documentation

Whether medical products or diagnostics: ENGEL GMP documentation enables you to perform a comprehensive, well-founded system qualification.

iQ weight control

This digital assistance system reacts to changes in melt viscosity and automatically adjusts the switchover point and holding pressure. The part weight remains exactly the same, even under fluctuating conditions.

e-mac

The all-electric e-mac is characterised by a minimal footprint combined with great flexibility in machine configuration.