Simulate injection moulding more efficient by using sim link

Why does Intercable need a data interface like sim link for simulating injection moulding?

Every injection moulder faces challenges in achieving its production targets. The most important factor in the development of new products is a short time to market. At the same time, the costs for the development and the optimisation of the moulds must be kept low.

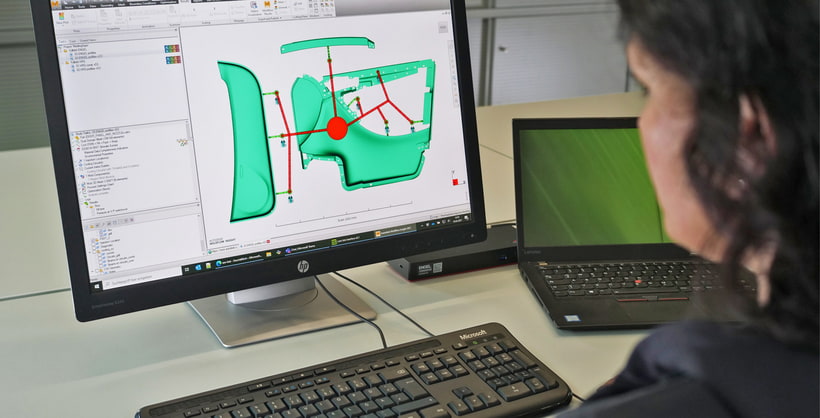

Experimental methods such as filling studies are often not sufficient. Analytical methods lead to better results. That is why software for simulating injection moulding is crucial for success. Here, however, the problem often arises of establishing a smooth data exchange between software and production.

This is exactly what is possible with ENGEL sim link , because it combines simulation and real production. sim link makes problem-free data exchange between simulation and the injection moulding machine possible. This saves time consuming co-ordination loops between mould development and production.

These iterations during pilot sampling were also the decisive point why Intercable chose sim link.

Simulation on its own does not add value. In contrast, production creates only limited results without the help of simulation. With sim link, we now have the opportunity to close this gap. Product development is now directly linked to production.

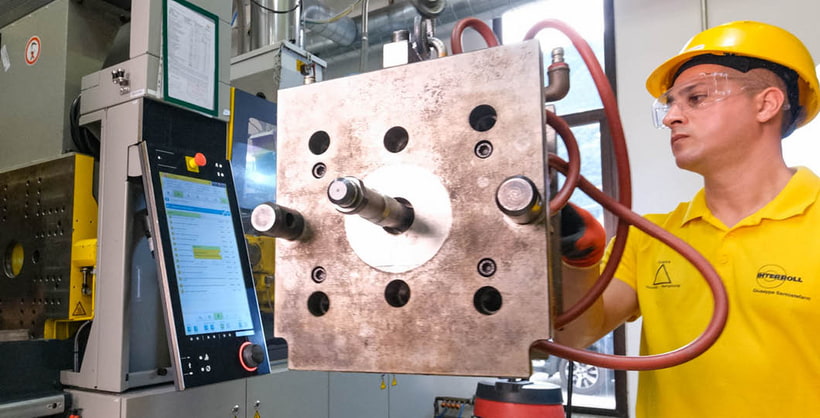

![[Translate to Englisch:] Gianluca Cappella | Intercable [Translate to Englisch:] Bild zeigt Werkzeugbauer bei Intercable](/fileadmin/_processed_/3/6/csm_gianluca_cappella_sim_link_02_3543eed7d5.jpg?noindex=1)

How have the challenges for Intercable been solved by sim link?

Each iteration of the process costs valuable time and a lot of money. Therefore, it is essential to bring the production specialists together with the simulation engineers.

By using sim link, the number of repetitions could be significantly reduced. The quality of the simulation has also improved and become more accurate. Difficulties in the coordination could thus be successfully overcome.

Some successes have been achieved with sim link:

- potential problems are eliminated before the mould is even built

- reduced risk of delayed production start-up

- project costs remain within budget

sim link helps to reduce the time needed to fine-tune the process parameters. The savings depend on the material type and part geometry and range from 10 to 50 %.

Simulate injection moulding: What are the advantages with ENGEL sim link?

Higher quality of the simulation

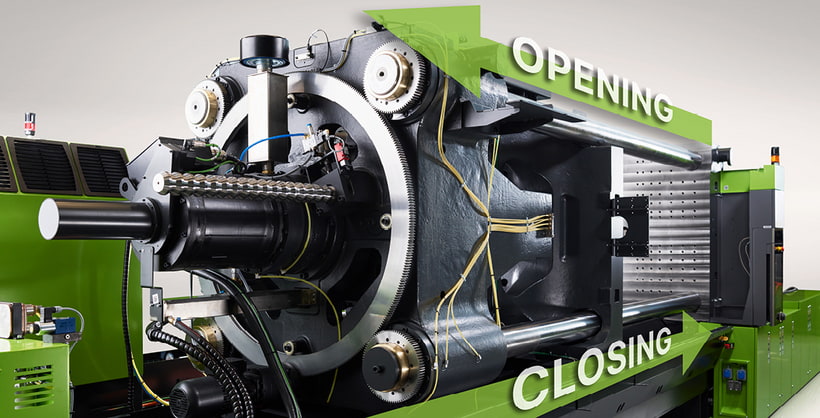

The individual machine dynamics are taken into account and the simulation can be carried out more realistically. The measured production data can be fed back into the simulation very easily. This improves the quality of the simulation.

Shorter start-up phase

Thanks to effective simulation of injection moulding, cost-intensive looping is reduced when optimising a new component. Where mould makers had to find the values manually for the initial sampling of the moulds, target values are now automatically transferred from the simulation to the injection moulding machine.

Ensured data consistency at every stage

Time-consuming and error-prone manual input of data at the machine is no longer necessary. sim link fulfils this data exchange between simulation software and injection moulding machine without errors.

Easy collaboration across different departments

Several experts are involved in the creation of a new product. sim link simplifies cooperation between simulation and production staff.

Has the implementation of sim link for simulating injection moulding been worthwhile for Intercable?

Yes, it has from several points of view:

- The number of iterations during the initial sampling of the tools has been reduced.

- Coordination between the different departments has been facilitated.

- Error-prone manual processes were replaced by sim link.

- The time span from part design to series production has been shortened.

- The project costs remain within reasonable limits.

Simulating injection moulding with simulation software is now smoother and more cost-effective at Intercable.

By combining injection moulding simulation and sim link, the gap between simulation and production was closed simply and efficiently at Intercable. Intercable now uses the know-how from the detailed process simulation and thus simplifies the cooperation between the different disciplines. The time-to-market of the respective products has thus been considerably shortened.

Do you still have questions about the sim link data interface?

We will be happy to help you.

More about our products from the article

sim link

The bidirectional interface sim link enables data exchange between simulation software and injection moulding machine.

![Simulating injection moulding using ENGEL sim link :] Spritzgießen simulieren mithilfe von ENGEL sim link Picture shows Gianluca Capella working with sim link](/fileadmin/_processed_/1/0/csm_gianluca_cappella_sim_link_01_4316beffd7.jpg)